charpy notched bar impact test|charpy impact test sample dimensions : services 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the . webNosso site pode utilizar cookies para o funcionamento adequado dos seus recursos, com o objetivo de melhorar a sua experiência, permitir o início de sessão seguro, memorizar os detalhes de seu início de sessão, gerir a sessão e recolher estatísticas para oferecer o .

{plog:ftitle_list}

Resultado da Employee reviews for companies matching "quinto andar". 2 results for employers related to "quinto andar".

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod. For the test, a notched metal specimen is broken in half using a pendulum hammer.In a Charpy impact test to ISO 148-1, a notched metal specimen is severed .This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .Standards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy required to fracture a v-notched specimen. This energy .

charpy v notch toughness

charpy v notch testing standard

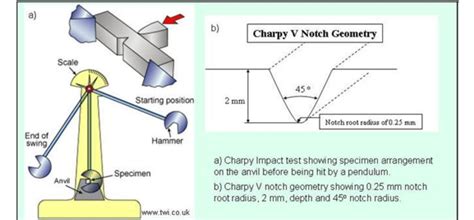

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the .There are two main forms of impact test, the Izod and the Charpy test. Both involve striking a standard specimen with a controlled weight pendulum travelling at a set speed. The amount of energy absorbed in fracturing the test piece is .In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .

Abstract: Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure .

The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be used as an economical quality .The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load .Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

oem ultrasonic thickness tester

charpy v notch testing requirements

oil tank thickness test

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the . 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .Methods for Notched Bar Impact Testing of Metallic Materials (E 23) has over the years been to standardize and control the variables associated with impact testing. This report looks at the history of impact testing, with emphasis on the key advances in understanding and application of the impact test, as reflected in the evolution of the testUnderstanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

Charpy Impact Test Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose • To determine the energy required to fracture a v-notched specimen. This energy translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1)Mechanical testing - Notched bar or impact testing - Part I. The previous article looked at the method of Charpy-V impact testing and the results that can be determined from carrying out a test. This next part looks at the impact testing of welds and some of the factors that affect the transition temperature such as composition and microstructure.Standard Test Methods for Notched Bar Impact Testing of Metallic Materials1 This standard is issued under the fixed designation E 23; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

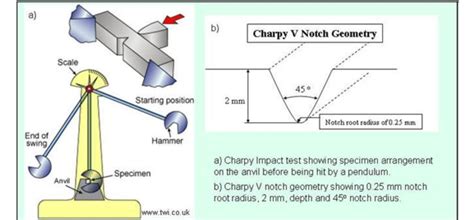

To successfully perform a Charpy V-notch impact test, the following steps must be followed for accurate results: 1. Notch test specimens. The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These .Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat. Scope1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see A

charpy v notch test procedure

ASTM E23 Test Standard outlines the procedure for conducting Notched Bar Impact Testing of Metals, commonly known as the Charpy impact test or the Izod impact test. Such tests cover the energy absorbed by notched metal specimens during one blow from a picked pendulum. The results are beneficial in delineating [.]

Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to .

Both Charpy & Izod impact testing are popular methods of determining the impact strength or toughness of a material. Learn comparisons from expert Lee Mangham. . Plastic samples are typically a 64 x 12.7 x 3.2 mm bar with a .Charpy impact testing is a low-cost and reliable test method for measuring the impact resistance of materials and is commonly required by construction codes for fracture-critical structures and pressure vessels. In its most common form (notched specimen Manuscript received June 13, 2018; accepted for publication October 4, 2018; published . Filler metals undergo rigorous testing to ensure they provide proper impact toughness to endure rapid loading, extreme temperatures or other stressors. The C.

Charpy impact test ? Part 2: Verification of the testing machine (pendulum impact) [2] ASTM E23, Standard test methods for notched bar impact testing of metallic materials [3] ISO Guide 34, General requirements for the competence of reference material producers [4] Scope: This standard specifies the requirements for notched-bar impact testing using both Charpy and Izod methods. It includes guidelines for specimen dimensions, preparation, and testing procedures. Specimen Dimensions: Charpy V-Notch: 55 mm length, 10 mm width, 10 mm thickness, with a 2 mm deep notch and a 45° angle.

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated.

one thick line pregnancy test

6.2.2 The procedures to verify Charpy machines indirectly, using verification specimens, are given in A2.4. Charpy impact machines must be verified directly and indirectly annually. Model parameters of J-C constitutive relation have been determined by quasi-static uniaxial tensile tests of smooth bar specimens and SHPB tests, and the damage parameters related to stress triaxiality of the J-C failure model were obtained by quasi-static uniaxial tensile tests of notched bar specimens. The Charpy impact test has been .

in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed by Russell. Because of Charpy’s early involvement with the notched bar pendulum impact test and his work toward standardization, this test is referred to throughout the world today .

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.Standard Test Methods for Notched Bar Impact Testing of Metallic Materials1 This standard is issued under the fixed designation E23; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A . Izod impact test; Both these tests use a notched bar with a defined cross-section as its specimen. And both specimens are stroke by a swinging pendulum. The differences between charpy and izod .

7 de fev. de 2023 · Latest odds and betting for the 2023 Mares' Chase. This Grade Two takes place on day four of the Cheltenham Festival on Friday 17th March. Allegorie De Vassy, Impervious, Scarlet And Dove and Jeremys Flame featured in the entries. Colreevy ridden by Paul Townend (front) jumps the last on the way to winning The Mrs Paddy .

charpy notched bar impact test|charpy impact test sample dimensions